About Us

Ceo Greetings

We, DOTEC Co. Ltd., are a professional & specialist valve manufacturing company with many years of proven track record.

JONATHAN KOO

We are dedicated to design, develop and manufacture a wide range of superior quality valves and customer-orientated in offering prompt service. This website illustrates the types and range of valves we manufacture and market; many of which are manufactured by us and some, with in-house QC tests and certification by our professional engineers, are trade items.

Our products are supplied locally and overseas worldwide for new and upgrading projects in chemical plants, petrochemical & thermal plants, oil-field and refinery applications - both onshore and offshore.

We are capable of providing timely technical solutions to meet customers specific applications and needs and will promptly attend to any urgent enquiry. With our long-standing experience & in-depth engineering knowledge in valve manufacturing we hope to satisfy your service & technical expectations in terms of quality, price, delivery and after sales service.

We always regard and value our customers as enduring partners in business and technological advancement.

WITH BEST WISHES & KIND REGARDS,

JONATHAN KOO

PRESIDENT & CEO

Our products are supplied locally and overseas worldwide for new and upgrading projects in chemical plants, petrochemical & thermal plants, oil-field and refinery applications - both onshore and offshore.

We are capable of providing timely technical solutions to meet customers specific applications and needs and will promptly attend to any urgent enquiry. With our long-standing experience & in-depth engineering knowledge in valve manufacturing we hope to satisfy your service & technical expectations in terms of quality, price, delivery and after sales service.

We always regard and value our customers as enduring partners in business and technological advancement.

WITH BEST WISHES & KIND REGARDS,

JONATHAN KOO

PRESIDENT & CEO

Brief History

1999

APR

Established DoTEC Co.,Ltd.

2000

NOV

Awarded the prime minister prize for export on Korean Export Day

2003

NOV

Certified ISO 90001 from ABS QE in USA

2004

APR

Started with Expansion of Casting Foundry

2004

DEC

Registered patent for Floating ball valves

2005

SEP

Registered patent for Trunnion ball valves

2005

Oct

Moved Factory to Jillye plants in Gimhae

2006

NOV

Obtained Fire safe certificates for Floating of Full and Reduced port ball valve from ABS

2006

NOV

Obtained Fire safe certificates for Trunnion of Full and Reduced port ball valve from ABS.

2006

NOV

Awarded the minister of industrial and energy for export on Korea Export Day

2006

DEC

Certified as qualified vender from PETRONAS in Malaysia.

2007

FEB

Obtained CE mark for Ball, Gate, Globe & Check valves.

2007

FEB

Certified as special company of parts and materials.

2007

FEB

Established a research institue

2007

OCT

Registered trade mark "DoTEC".

2007

NOV

Certified as qualified vender from TOSHIBA in Japan.

2008

JAN

Certified for INNO-BIZ company from the small & medium business administration

2008

JAN

Registered patent for the top entry metal seat ball valves

2008

APR

Certified of Venture Company.

2008

JUN

Promising Export Firm by the Small & Medium Business Administration

2008

AUG

Obtained Certificate of Authority to use the official API Monogram

2009

SEP

Development of special industrial Top Entry Ball Valve

2011

FEB

Obtained Certificate of GOST

2011

APR

Development of Ultra Pressure Swivel Joint and Hose loop.

2011

DEC

Certified the Clean Work Place.

2012

MAY

Development of DLC(Dimond-Like-Carbon) coating technology

2014

JAN

Certified ISO 14001 from G-CERTI

2014

MAY

Obtained EAC certificate for Russia, Belarus & Kazakhstan.

2015

APR

Awarded the New Korean Grand Prize of the Year 2015

2015

NOV

Awarded the $3 million export tower on Korea Export Day.

2019

APR

Registered patent for Valve tester

2019

JUN

Moved Company to Technovalley Industrial Complex.

2020

JAN

Development of Top Entry ball valves for cryogenic service

2022

JUN

Awarded the Korean Consumer Best Brand - Customer satisfaction valves

2023

MAR

PAT certified for Ball, Gate, Globe, Check, SBB and Butterfly valve from ABS

2023

MAY

Certified Approval maker for Butterfly, Gate, Globe, Check & Ball valve from Korea South-East Power CO. LTD., Korea Southern Power CO., LTD., Korea East-West Power CO., LTD., Korea Western Power CO., LTD. Korea Midland Power CO., LTD

2023

JUN

Obtained Fire-safe certificates for Top Entry Trunnion type ball valve from Apave

2024

APR

Development of Compact ball valves

Head Office

Factory

Assembly & Testing Factory

Machining Factory

Machining facility 1

QA Meeting room

Quality control Facility

Bulletin Room

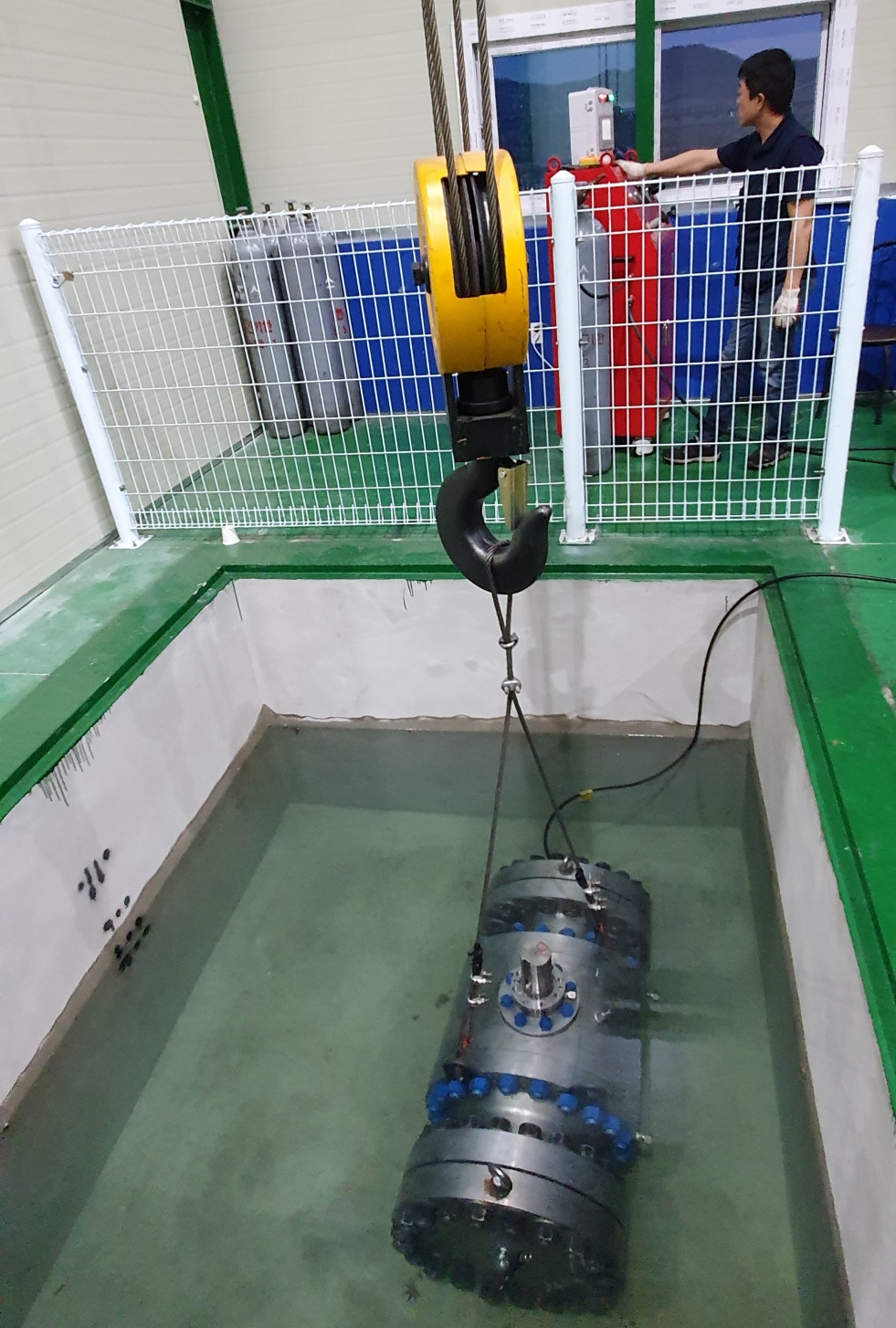

Test of Facility 1

Manufacturing Facility

Inside the Office

Test of Facility 2

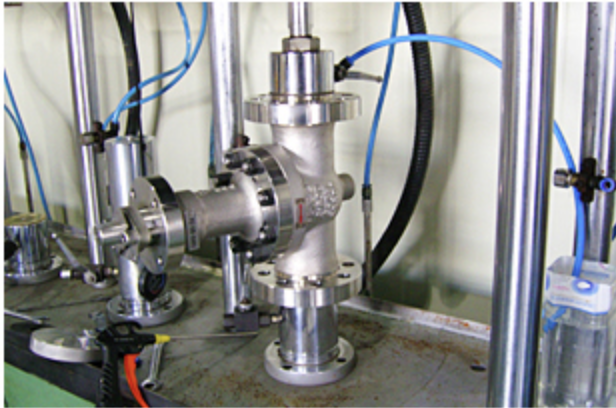

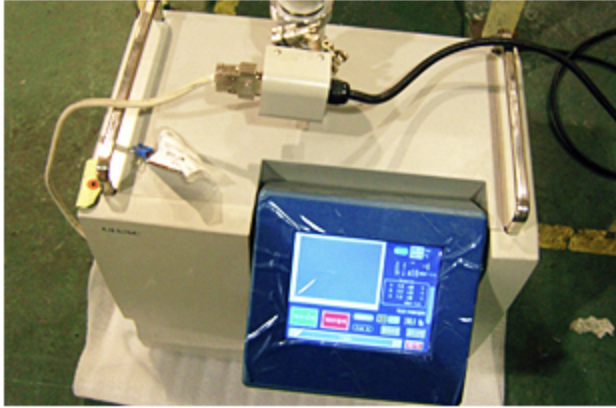

Hydro Tester

Test of Facility 3

Clean Room

Finished goods 1

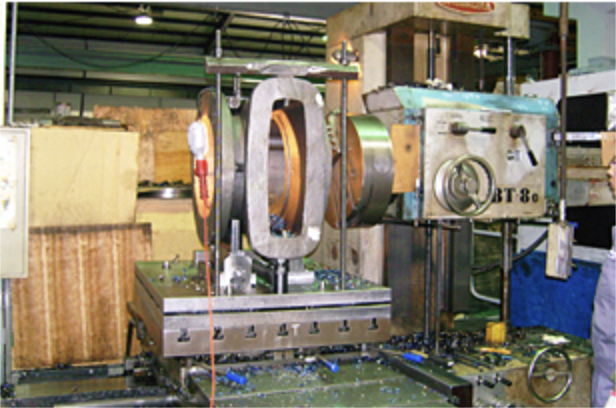

Cryogenic Test at - 196'C

Finished goods 2

High temperature at 500'C

Packing area 1

Shell Test

Packing area 2

Cycle Test of Swivel Joint

N2 Test

Helium Test Machine

Machining

Assembly

We are Building a Sustainable Future